I have more data. I apologize for the long post. TL;DR - Use an enclosure with push/pull fans, the thermal compound on the heatsinks is not thermal compound; using real thermal compound decreases temperatures by up to 4 deg C.

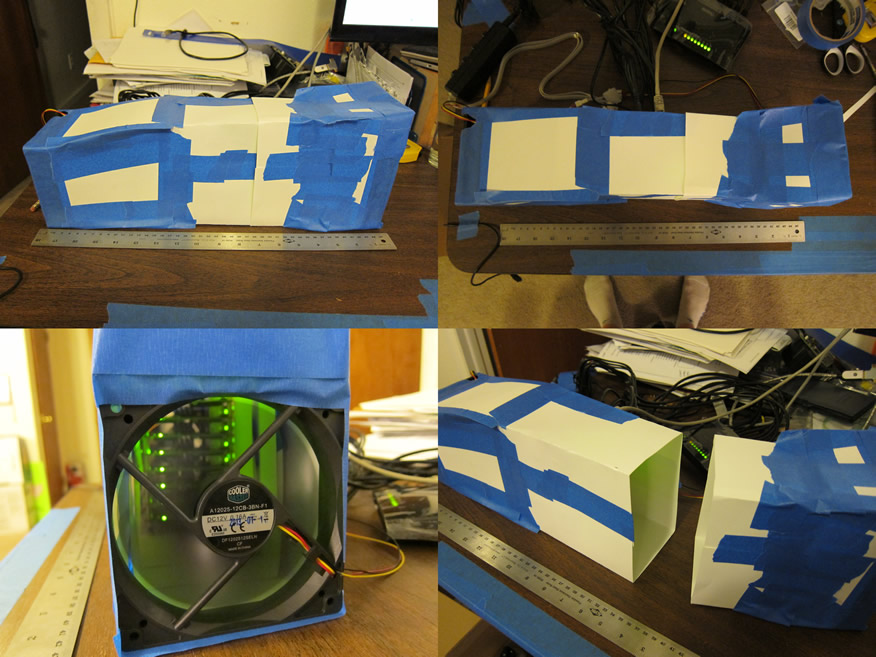

I built a cardstock case to direct the flow of air more cleanly, shown below. The setup is push/pull; I tried to block as many openings as possible. The end with the pulling fan is detachable so I can access the reset buttons (I am still having grief with eth0 not coming up properly).

- enclosurecollage-small.jpg (157.43 KiB) Viewed 28750 times

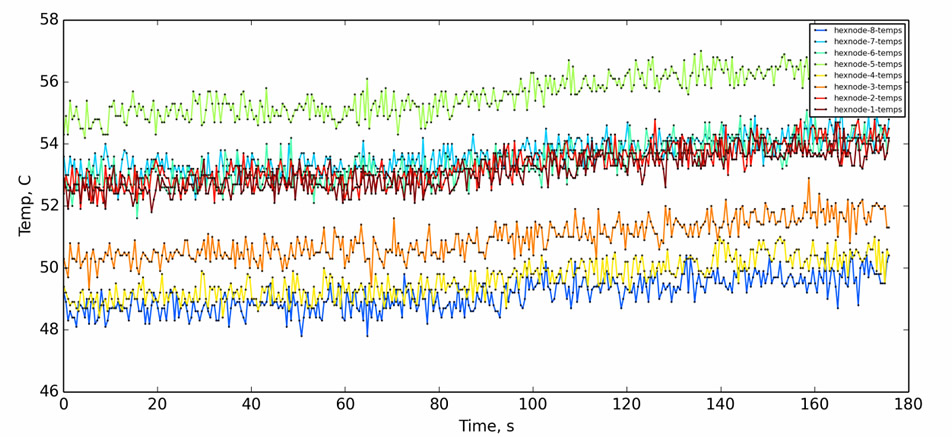

The graph below shows the temperatures with and without the pull fan attached to the enclosure. The transition occurs around 60 s, leveling off around 120 (as best I can tell). Like in my original post, the vertical board position corresponds to vertical position in the legend.

- enclosedairflow.jpg (140.41 KiB) Viewed 28750 times

My observations:

1) The enclosure makes the cooling more consistent, and for the most part drops the temps about 2 deg C.

2) Using push/pull instead of just push with the enclosure gives approximately 2 deg C additional drop.

3) I wondered why board 5 was running hot compared to the other boards. The best hypothesis I can come up with is that the chip runs slightly hot compared to the others; I examined the placement of the heatsinks to see if there was any observable difference.

I randomly (and accidentally) pulled one of the heatsinks off my boards. this seemed weird to me, because I thought the

silver stuff was a thermal compound. Ha, no, it's some kind of tin foil.

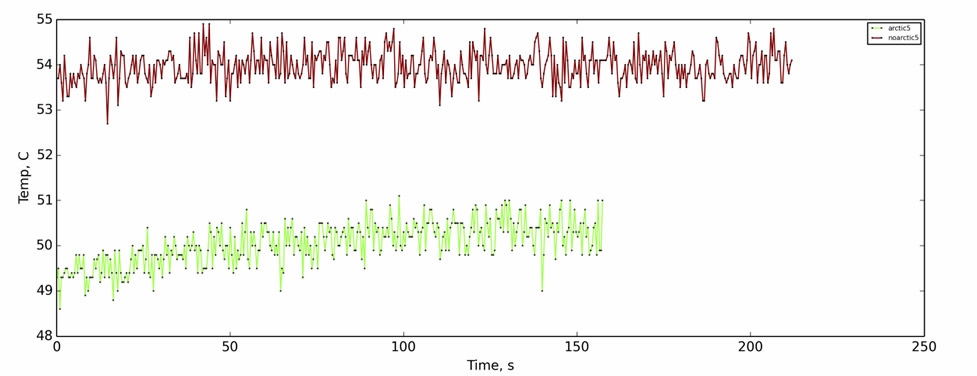

So I conveniently have some Artic 5

silver compound sitting around, so I decided to see what the temperature difference between the two might be. I scraped off the tin foil, cleaned off the heatsinks with 70% isopropyl, and applied artic

silver. I put single board in my enclosure, with and without Arctic 5 applied. Here are the results:

- thermalcompound.jpg (59.04 KiB) Viewed 28750 times

As you can see, you can decrease the temperature by about 4 C by using proper thermal compound, versus weird

silver foil stuff. I don't necessarily endorse this modification of the setup, but honestly it makes a non-trivial difference. Maybe someone in the Adapteva crew can endorse the use of thermal compounds so everyone can enjoy lower (and safer) temps?

At this point, the only experiment left that I can think of to try is longer standoffs, but I don't have any at the moment. I'm not sure how much of an impact that would make, either. Short of liquid cooling, I think this is probably the best anyone can do (although, someone please prove me wrong).